Surface Emitting LED structure, working, advantages, disadvantages

This page covers structure, working operation, advantages and disadvantages ofSurface Emitting LED. It mentions Surface Emitting LED advantages or benefits and Surface Emitting LED disadvantages or drawbacks.

Surface Emitting LED structure | Surface Emitting LED working operation

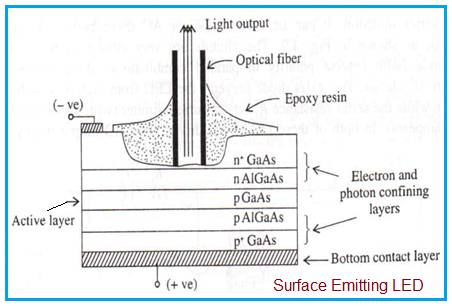

• It is modified form of DH LED (Double Heterojunction LED). In this LED type, optical fiber is butt-coupled with itself. This is shown in the figure-1.

• The surface emitting LED structure consists of thin central active layer of p type GaAs.

• This central layer is bounded by n-type AlGaAs/n+-type GaAs at the top side.

• This central layer is bounded by p-type AlGaAs/p+-type GaAs at the bottom side.

• The extreme top n+type GaAs and bottom p+-type GaAs layers are used to provide low resistive ohmic contacts only.

• The external optical fiber is butt connected by etching the top layers and by shielding with epoxy resin.

• When refractive indices of both p-type and n-type materials are same, light is free to come out from all the sides of the semiconductor device due to no confinement. However only active region near the surface will emit the significant amount of light while absorbing from the other parts. Hence it is known as surface emitting LED.

• Output radiation is originated from central thin layer i.e. p-type GaAs layer.

• Maximum optical power Pc is coupled with the optical fiber is expressed as follows.

• Pc = π * (1-R) * A* Rs * (NA)2

Where,

R = Reflection loss at fiber surface

A = Fiber cross section area

Rs = Radiance amount from source

NA = Numerical Aperture

Benefits or advantages of Surface Emitting LED

Following are the benefits oradvantages of Surface Emitting LED:

➨Optical coupling coefficient of LED with external fiber system is relatively higher. Hence this LED offers high optical coupling efficiency.

➨Optical loss (due to internal absorption) is very low. This is because of carrier recombination near its top heterojunction.

➨InP/InGaAsP based LED is used for long wavelength applications.

➨It offers higher efficiency with low to high radiance.

➨The top n-GaAs contact layer ensures low thermal resistance and contact resistance. This allows high current densities and high radiation intensity.

➨The internal absorption in the device is very low due to larger bandgap confining layers. Moreover reflection coefficient at the back crystal face is high which gives good forward radiance.

Drawbacks or disadvantages of Surface Emitting LED

Following are the drawbacks ordisadvantages of Surface Emitting LED:

➨The surface emitting LED can transmit data rate less than 20 Mbps than edge emitting LED.

➨It contains short optical link with large NA (Numerical Aperture).

Also refer advantages, disadvantages and basics ofEdge emitting LED >>andDouble heterojunction LED >>.

Advantages and Disadvantages of other wireless technologies

What is Difference between

OFDM和OFDMA的区别

Difference between SC-FDMA and OFDM

Difference between SISO and MIMO

Difference between TDD and FDD

FDMA vs TDMA vs CDMA

FDM vs TDM

CDMA vs GSM